Dunline® Rubber Compressive Shrinkage Belts

Since the first Dunline Endless Rubber Compressive Shrinking Belt was sold in 1938 Dunline Rubber Belts have been universally recognized as the superior belt. Due to our formula, our construction technique, and our years of experience, our belt outperforms anything else on the market. Whether used for most the delicate fabrics requiring the finest belt finish or the thickest denims requiring the highest and most consistent shrinkage, the Dunline name is synonymous with quality.

Natural Rubber Formula

- Original Dunlop® Formula – the industry standard

- Better resistance to tearing, cracking, elongation, abrasion, and the negative effects of heat and chemicals

Thin Ply Calender Construction

A continuous calendared thin rubber sheet (ply) is rolled onto a 3962mm diameter drum, eliminating all surface seams and reducing chances for

- Original Dunlop® Formula – the industry standard

- Better resistance to tearing, cracking, elongation, abrasion, and the negative effects of heat and chemicals

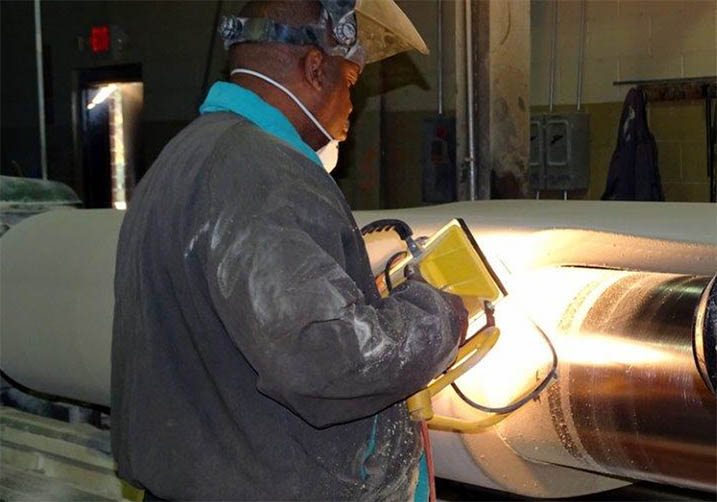

Export Belt Finishing

- Precision ground to a fine finish – typically no need to grind prior to use.

- Interior buffed to ensure all rolls turn properly.

Edge Types

Straight

- Maximizes face width of belt for wider fabrics

Regular

- Large face width for wide running of fabric

- Helps reduce edge stress

Contour

- Excellent for minimizing edge stress and cracking

Crates

- Crate made specifically for each individual belts – dimensions adjusted for different belt sizes

- Front panel opens for easy removal & inspection by customs

- Helps reduce compression set